TCM Cushion Tire Forklifts Houston

On the market nowadays are forklifts that are classed in 7 various categories. Classes 1-4 consist of forklifts that are designed particularly to utilize on smooth surfaces indoors. They might be chosen for particular aspects of recycling that happen in those types of environments. For more rigorous outdoor recycling applications, Class V and VII forklifts are usually used.

There are many company operations that work outdoors and have to deal with extreme workloads. Their lift truck selection would gravitate toward IC or Internal Combustion machinery in Class VII and Class V. These units work well in any climate and have enough power to run heavy things during the course of a shift.

A different important factor to take into account is to use a lift truck safely. Knowing and acknowledging the center of gravity is really essential when driving a forklift, particularly while traveling on uneven terrain. Recognizing the stability triangle in these difficult work conditions is also imperative.

Warehouses, manufacturing operations, and the supply area for numerous textile firms can have various kinds of reach trucks. Utilizing a reach truck to store finished merchandise on pallets, a range of supplies and other pieces of machines is common. These kinds of machines really help to keep a facility organized and allow them to utilize the maximum amount of area by stacking vertically. Reach trucks are fairly easy to utilize. They could help make better use of both time and available storage space.

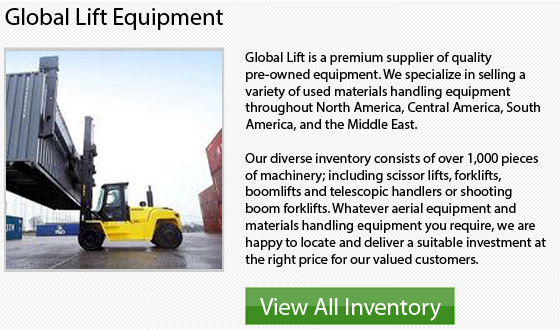

If you are going to be utilizing your forklift equipment 4 to 8 hours a day, it is highly recommended to buy brand new. The warranty alone could come in handy with such continuous use. If, however, you are only loading and unloading on a bi-weekly basis or not very often, then a used model can be suitable for your requirements. Each and every situation is different and you must evaluate your personal requirements prior to selecting a suitable equipment.

- Terex Aerial Work Platforms Houston

Overview Telescopic booms provide much greater horizontal outreach compared to different kinds of aerial platform equipment. They are the ideal choice for places that have limited access in industrial applications and construction. Terex Telescopic S-Booms... More - JLG Knuckle Boom Lift Houston

Turn the Corner on Efficiency The E Series boom lifts are environmentally friendly and offer industry-leading performance. You could select from 3 platform heights and a variety of chassis widths to best meet your work... More - Caterpillar Narrow Aisle Forklifts Houston

Narrow Aisle Forklift A narrow aisle forklift is utilized for lifting and lowering loaded pallets from high storage spaces. This type is suitable for work environments with narrow spaces between aisles, such as warehouses or... More - Skyjack Electric Scissor lifts Houston

Classifications of Aerial Lift Platforms & Scissor Lifts Aerial platforms and scissor lifts enable employees to work on elevated structures since they can reach lots of objects and structures. These lifts provide friendly user controls... More - Hyundai Stand Up Forklifts Houston

Skills of a Stand Up Forklift Operator The powered industrial truck or forklift is a heavy duty machine found in almost every factory and warehouse. These reliable and tough equipment can raise and transport heavy... More