Hyundai Dual Fuel Forklifts Houston

Forklifts

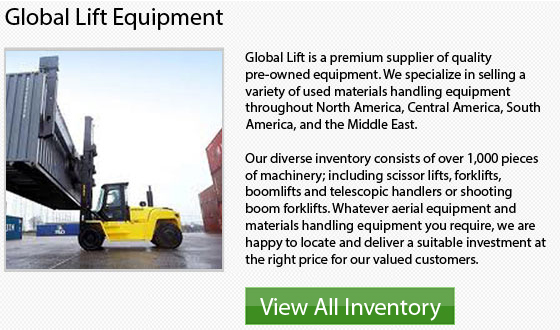

In material handling, construction, manufacturing and warehousing applications, forklifts are commonly utilized to transport and lift palletized loads. With manual-drive forklifts, the travel or load movement is either walk-behind or manually powered. Motorized drive forklifts have a motorized drive. In various models, the forklift has a protected seat or cab for the driver. Fork trucks include features like for instance cabs, and backup alarms and are also motorized. Some kinds of forklifts are counterbalanced so as to prevent the vehicle from turning over. Other models come equipped with safety rails, or a rotating element like for instance a hand rail or a turntable.

The stroke and lift capacity are other specification that you should take into account when selecting a kind of forklift. Lift capacity is defined as the supportable, maximum force or load. Stroke is defined as the difference between fully lowered and fully raised lift positions.

Several of the other key specifications for the forklift are fuel type and tire type. The available fuel choices are: LP or liquid propane, natural gas, electricity, compressed natural gas or CNG, diesel, gasoline or propane.

For fork trucks and forklifts, there are two basic types of tires which could be utilized. They are: pneumatic and solid. The solid or cushion tires require less maintenance than pneumatic tires and do not easily puncture. Air-inflated or pneumatic tires provide load cushioning and great drive traction. At the end of the day, solid or cushion tires provide less shock absorption.

Usually used on rough terrain are Class VII forklifts. These kinds of machinery are often utilized in agriculture, construction and in logging environments. Lastly, Class VIII forklifts have all burden and personnel carriers. Dual Fuel lift trucks often fit in this class.

- Terex Aerial Work Platforms Houston

Overview Telescopic booms provide much greater horizontal outreach compared to different kinds of aerial platform equipment. They are the ideal choice for places that have limited access in industrial applications and construction. Terex Telescopic S-Booms... More - JLG Knuckle Boom Lift Houston

Turn the Corner on Efficiency The E Series boom lifts are environmentally friendly and offer industry-leading performance. You could select from 3 platform heights and a variety of chassis widths to best meet your work... More - Genie Zoom Boom Houston

During 1966, Bud Bushnell established Genie Industries. During that time, he purchased the manufacturing rights to a material lift that functioned on compressed air. The name Genie came from the "magic in the bottle" that... More - Jungheinrich LP Forklift Houston

The lift truck is an important piece of machinery in most companies that operate distribution centers, warehouses, storage handling and industrial facilities. This great machinery, the lift truck is constructed of numerous parts, like the... More - Hyundai Stand Up Forklifts Houston

Skills of a Stand Up Forklift Operator The powered industrial truck or forklift is a heavy duty machine found in almost every factory and warehouse. These reliable and tough equipment can raise and transport heavy... More