Jungheinrich Dual Fuel Forklift Houston

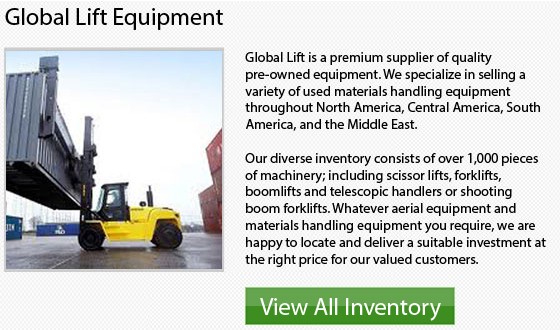

Essential equipment used on construction sites includes vehicles like the forklift, the bobcat and the bulldozer. Lift trucks can range from really huge to quite small versions. These kinds of machines are designed to raise loads and move materials and goods within retail or warehouse settings. A lot are made to easily maneuver within narrow, confined areas. It takes skill and training to master a lift truck.

The forklift can be found in nearly every warehouse, factory, and distribution center because they have become vital pieces of machines used for handling materials. Inside warehouses and stockrooms, the lift truck is utilized to lift and move goods and supplies to store them up high. They are essential for production in work settings where there is a small area to store a large array of stock. These kinds of trucks are made to transport large pallets around inside warehouses.

Anyone utilizing a forklift should be trained how to operate and drive this piece of equipment. Training can be done in a formal training setting or on the job. usually training is offered at the workplace. Training and accreditation normally means a pay raise for the individual obtaining new skills. Lift trucks have standard operating procedures, which makes it easy to get taught on various types of forklifts.

The cab on smaller forklifts support just one worker who is able to move the machine in small areas. The bigger machines are massive and can carry trucks, automobiles or other heavy pieces of equipment. Forklifts could easily lift thousands of pounds.

Typically, construction companies will give salary raises to workers who go through training. Employers would usually send a worker to classes to train on a huge piece of equipment. Willingness to train on a lift truck, a bobcat or a bull dozer would pay off.

- TCM IC Forklifts Houston

Ever since their launch in the material handling business during the 1920s, forklifts have gone through a huge evolution. These days, these machines are a lot stronger and smarter. They have changed the material handling... More - Taylor Large Capacity Forklifts Houston

Taylor Machine Works has engineered and developed the T-Series machinery which would handle the most difficult tasks required for materials handling. The rigid chassis construction, along with the highest quality parts and the matched power... More - Genie Zoom Boom Houston

During 1966, Bud Bushnell established Genie Industries. During that time, he purchased the manufacturing rights to a material lift that functioned on compressed air. The name Genie came from the "magic in the bottle" that... More - Jungheinrich LP Forklift Houston

The lift truck is an important piece of machinery in most companies that operate distribution centers, warehouses, storage handling and industrial facilities. This great machinery, the lift truck is constructed of numerous parts, like the... More - Hyundai Stand Up Forklifts Houston

Skills of a Stand Up Forklift Operator The powered industrial truck or forklift is a heavy duty machine found in almost every factory and warehouse. These reliable and tough equipment can raise and transport heavy... More