Jungheinrich Double Reach Forklifts Houston

Forklift Material Handling

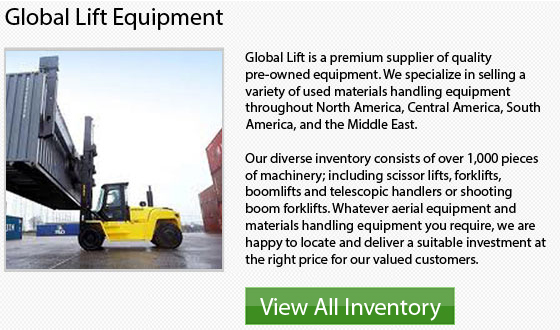

Companies will eventually experience changes within the handling requirements over time. There are some factors utilized to be able to maintain optimal output such as expanded geographical coverage, more SKUs, and need to lower inventories. There have been many advances within material handling processes and technologies in the last several years. Several tools are evolving at an extremely fast rate and have the possibility to impact profitability significantly.

Lift Truck Battery & Charging Technology

Now is the perfect time to consider converting from traditional, internal combustion lift trucks to electric forklifts. The technology behind contemporary electric forklift charger and battery combinations is well ahead of the technological curve. Electric systems can provide more power for longer periods than ever before. The current series of electric forklift units offer run-times and capacities which exceed older units. Advancements in both battery and charger technologies help contribute to more environmentally sound practices inside factories throughout the globe.

The lithium-Ion batteries are considered the wave of the future because this important new technology is have a revolutionary effect on the usage of electric lift trucks. The advantages of Li-ion batteries are low maintenance and size and run times. They could be produced in smaller sizes compared to traditional lead acid batteries and are capable of holding up to six times the charge. They have zero memory, which allows them to maximize charging.

IC or Electric Lift Truck

Whether you are replacing an old truck or searching for your first forklift, think about investing in an electric lift truck. Keep in mind that the environmental, technological and legislative problems involved in forklift usage and technology is subject to change. Please review this easy-to-follow guidelines when thinking about whether an electric or an Internal Combustion truck best suits your specific requirements.

- TCM IC Forklifts Houston

Ever since their launch in the material handling business during the 1920s, forklifts have gone through a huge evolution. These days, these machines are a lot stronger and smarter. They have changed the material handling... More - Taylor Large Capacity Forklifts Houston

Taylor Machine Works has engineered and developed the T-Series machinery which would handle the most difficult tasks required for materials handling. The rigid chassis construction, along with the highest quality parts and the matched power... More - Genie Zoom Boom Houston

During 1966, Bud Bushnell established Genie Industries. During that time, he purchased the manufacturing rights to a material lift that functioned on compressed air. The name Genie came from the "magic in the bottle" that... More - Jungheinrich LP Forklift Houston

The lift truck is an important piece of machinery in most companies that operate distribution centers, warehouses, storage handling and industrial facilities. This great machinery, the lift truck is constructed of numerous parts, like the... More - Hyundai Stand Up Forklifts Houston

Skills of a Stand Up Forklift Operator The powered industrial truck or forklift is a heavy duty machine found in almost every factory and warehouse. These reliable and tough equipment can raise and transport heavy... More